| Grit : | P120# and P220# |

| Normal Size : | 80x1180mm |

| Minimum Order : | 1 Pcs |

| Delivery Time : | 3-5 days |

| Payment Terms : | T/T, Western Union, Paypal |

| Supply Ability : | 20,000 Pcs per year |

| Product Price : | Negotiable |

| About Package : | Carton, wood pallet |

● Specially developed by using new technology with high quality artificial diamond.

● Has the dual advantages of softness of traditional abrasive and high hardness of diamond.

● Be available in a wide range of belt backers and a wide variety of grit sizes.

● Compared with traditional sanding belts, the characteristics of Diamond/CBN sanding belts are of high grinding efficiency, long working life, excellence smoothness, high cost-effective, little dust and low noise.

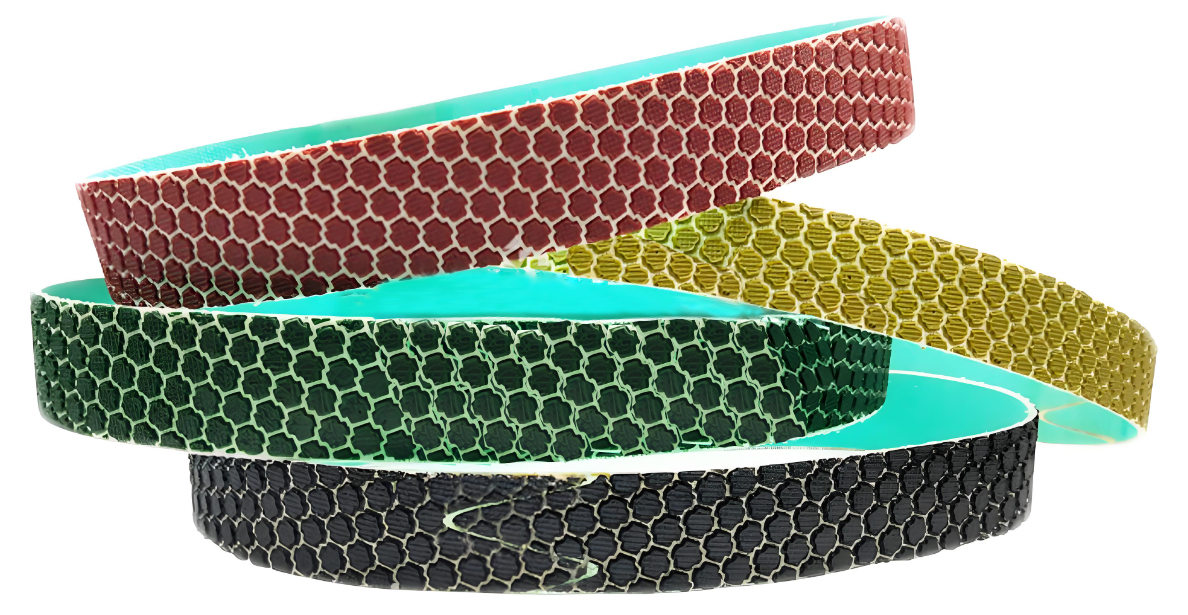

Resin Diamond Belts

Resin diamond belts are mainly used in grinding and polishing hard materials. Continuous layer of resin, diamond is all the way through the resin. The resin diamond coated belt can be used for various applications, for wet usage.

The difference between with Metal Bond and Resin Bond:

● The grinding units of the belt’s surface are different, electroplated belt is small dot pattern, resin diamond belt is rectangle pattern.

● The electroplated belt is more aggressive and sharp than resin diamond belt, but the resin diamond belt is more durable than electroplated belt.

● With same grit grade, resin belt have more better polishing effect on surface roughness than electroplated belt.

● Both of them need wet grinding, and resin belt need more proper grinding pressure during operation.

● The costs of resin belts is more expensive than electroplated belts.

● 1. In terms of binders, resin diamond grinding wheels mainly use phenolic resin with a small amount of metal powder as binders, while electroplated diamond grinding wheels use electrodeposition to deposit nickel cobalt alloy on the surface of the metal substrate and fix the diamond abrasive.

● 2. In terms of processing efficiency, electroplated diamond grinding wheels use higher grade abrasives with only a single abrasive layer, and have better heat dissipation performance, resulting in higher processing efficiency.

● 3. In terms of service life, electroplated grinding wheels only have one layer of abrasive, resulting in a shorter service life than resin diamond grinding wheels.

● 4. In terms of processing accuracy, under the same particle size conditions, electroplated grinding wheels have a greater impact on the surface roughness of the workpiece.that is to say, electroplated diamond is more suitable for rough grinding, while resin diamond is more suitable for fine grinding

● Diamond sand belts are widely used as thermal spraying materials, high-speed steel, special ceramics, monocrystalline silicon, polycrystalline silicon, gemstones, silicon aluminum alloys, hard alloys, stainless steel plates, silicon steel sheets, aluminum plates, copper plates, particleboard, plywood, fiberboard, leather, insulation board, ceramic board, automotive glass, stone, and aerospace, etc

● CBN sanding belts are mainly used for grinding and polishing iron-base alloys, titanium alloys, stainless steel, high-temperature alloys, etc.

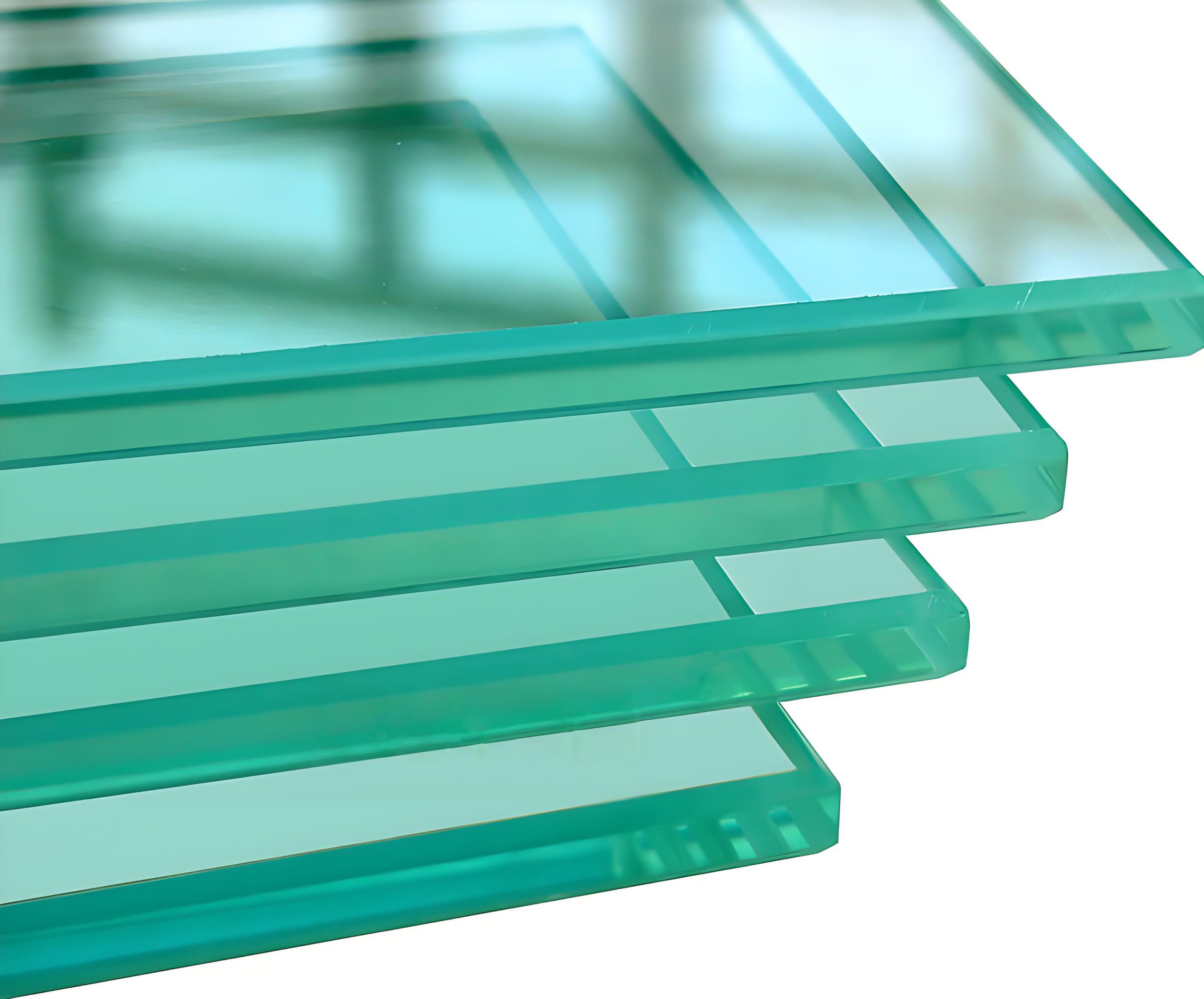

● Grinding and polishing of high hardness materials: Diamond abrasive belts are particularly suitable for grinding and polishing materials with high hardness, such as glass, ceramics, stone, metals, etc., due to their extremely high hardness.

● Precision machining: Diamond abrasive belts can be used for precision machining processes, such as polishing and fine machining of optical glass, as well as machining of workpieces that require high precision and surface smoothness.

● Long lifespan and stability: Diamond sand belts have a very long service life and stable processing performance, which can maintain high efficiency in high-intensity working environments for a long time.

● Efficient processing: Due to the special material and design of diamond abrasive belts, they can provide fast and accurate processing, improving production efficiency and product quality.

● Processing requirements for special materials: For some special materials, such as high-strength alloys, hard alloys, etc., diamond abrasive belts are commonly used processing tools that can meet their special processing needs and requirements.

● Environmental advantages: Diamond electroplating sand belts have the environmental characteristics of low dust and low noise, and are widely used in processing scenarios that require environmental protection requirements.

Lenth 150mm~5000mm; Width 5mm~350mm; Grit P40~5000

Specifications of commonly used sanding belts for polishing glass edges: 80x1180mm(3" x 47")

Granularity: 120 #&220#

Other specifications can be customized, and the grit can also be specified.

● Specially developed by using new technology with high quality artificial diamond.

● Has the dual advantages of softness of traditional abrasive and high hardness of diamond.

● Be available in a wide range of belt backers and a wide variety of grit sizes.

● Compared with traditional sanding belts, the characteristics of Diamond/CBN sanding belts are of high grinding efficiency, long working life, excellence smoothness, high cost-effective, little dust and low noise.

Normal Size: 80x1180mm, Grit:120# and 220#

Other specifications can be customized

| Model | Length | Width | Big Width | Grit |

| No. | mm | 5~100mm | 100~350mm | No. # |

| BSD-96481 | 150 | ● | 40~2000 | |

| BSD-96482 | 200 | ● | 40~2000 | |

| BSD-96483 | 250 | ● | 40~3000 | |

| BSD-96484 | 300 | ● | 40~3000 | |

| BSD-96485 | 350 | ● | 40~3500 | |

| BSD-96486 | 400 | ● | 40~3500 | |

| BSD-96487 | 450 | ● | 40~4000 | |

| BSD-96488 | 500 | ● | ● | 40~5000 |

| BSD-96489 | 600 | ● | ● | 40~5000 |

| BSD-96490 | 800 | ● | ● | 40~5000 |

| BSD-96491 | 1000 | ● | ● | 40~5000 |

| BSD-96492 | 1200 | ● | ● | 40~5000 |

| BSD-96493 | 1500 | ● | ● | 40~5000 |

| BSD-964494 | 2000 | ● | ● | 40~5000 |

| BSD-96495 | 2500 | ● | ● | 40~5000 |

| BSD-96496 | 3000 | ● | ● | 40~5000 |

| BSD-96497 | 3500 | ● | ● | 40~5000 |

| BSD-96498 | 4000 | ● | ● | 40~5000 |

| BSD-96499 | 4500 | ● | ● | 40~5000 |

| BSD-96500 | 5000 | ● | ● | 40~5000 |

12

Focus on high-tech production for 12 years50

Exported to 50 countries and regions6000

Covers an area of 60,000 square metersTechnology

The production technology and process of synthetic diamond are becoming more and more mature. China's output of synthetic diamond accounts for more than 90% of the world's total output of synthetic diamond, and has become the largest producer of synthetic diamond in the world. As the quality of domestic products is difficult to meet the industry standard of diamond cutting line and the output of refined nickel is insufficient, most manufacturers rely on foreign imports. The following is an analysis of the current situation of the diamond industry.

>> Learn moreBrand Development

The production technology and process of synthetic diamond are becoming more and more mature. China's output of synthetic diamond accounts for more than 90% of the world's total output of synthetic diamond, and has become the largest producer of synthetic diamond in the world. As the quality of domestic products is difficult to meet the industry standard of diamond cutting line and the output of refined nickel is insufficient, most manufacturers rely on foreign imports. The following is an analysis of the current situation of the diamond industry.

>> Learn morePlease review our products. Thank you for your support

Quality of Product

5

Value of Product

5

Ease of use

5

Effectiveness

5

Durability

5

Here is your enquiry list